Product Description

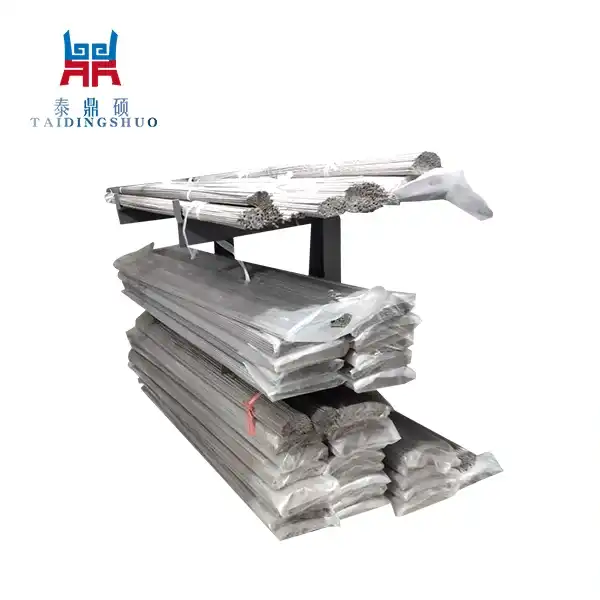

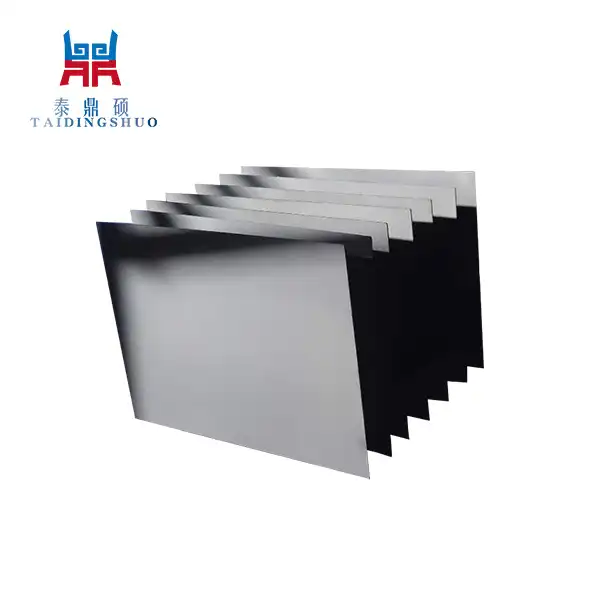

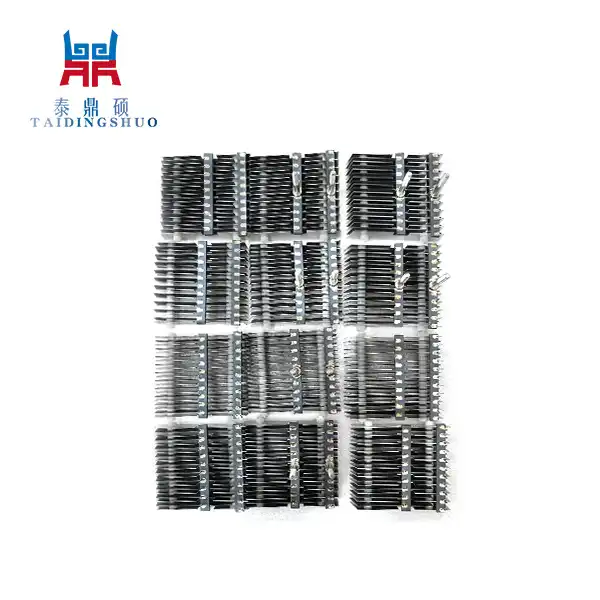

Basic Product Details:Our Titanium anode for molten salt electrolysis is meticulously crafted to meet the demanding requirements of various industrial electrolysis processes. Made from high-quality titanium material, our anodes ensure exceptional performance and durability in corrosive environments. With a focus on precision engineering and stringent quality control, Tai Ding Shuo Industrial Co., Ltd. delivers cutting-edge solutions for electrolytic processes across industries.

Product Standards

- Compliant with international quality standards

- Rigorously tested for performance and durability

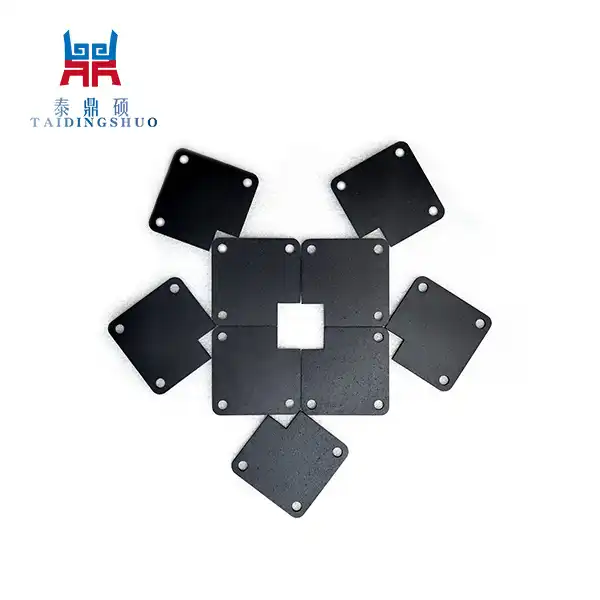

- Customizable to meet specific application requirements

Basic Parameters

- Material: Titanium

- Coating: IrO2, RuO2, Pt, etc.

- Shape: Plate, mesh, ribbon, etc.

- Size: Customizable

Product Attributes

- Corrosion resistance

- High conductivity

- Long service life

- Customizable design

- Stable performance in harsh environments

Product Functions

Our Titanium anode serves as the critical component in molten salt electrolysis, facilitating the electrochemical reactions necessary for various industrial processes. It enables efficient production of metals, chemicals, and other essential products through electrolytic processes.

Features

- Advanced coating technology for enhanced durability

- Tailored design options to meet specific application needs

- Exceptional corrosion resistance in harsh chemical environments

- High conductivity for efficient electrolysis

- Consistent performance over extended operating periods

Advantages and Highlights

- Superior corrosion resistance extends anode lifespan

- Customizable design ensures compatibility with diverse applications

- High conductivity enhances electrolysis efficiency

- Robust construction withstands harsh operating conditions

- Exceptional performance delivers consistent results

Application Areas

Metal refining (for example, magnesium and aluminum)

Alkali-Chloride Production

Electroplating

Treatment of water

Substance Combination

OEM Services

At Tai Ding Shuo Modern Co., Ltd., we value conveying exhaustive OEM administrations created to address the exact necessities of our regarded customer base. Our experienced professionals collaborate with clients to conceptualize and engineer bespoke solutions that are precisely tailored to their specific application requirements.

Through a consultative methodology, we dive profound into figuring out the complexities of each task, permitting us to devise inventive and tweaked arrangements that impeccably line up with our clients' goals. Whether it's adjusting existing items to suit specific applications or designing completely new arrangements from the beginning, our devoted group is focused on conveying greatness at each phase of the OEM cycle.

We maintain a constant focus on precision, dependability, and customer satisfaction from the initial ideation and design stage through prototyping, manufacturing, and quality assurance. Each solution that we provide not only meets but also exceeds the expectations of our clients is the result of our unwavering commitment to craftsmanship and attention to detail.

We at Tai Ding Shuo Industrial Co., Ltd. are your reliable innovation partner, enabling you to accurately and confidently realize your vision. Reach us today to find how our fitted OEM administrations can raise your undertaking higher than ever of achievement.

Certifications:

FAQs

-

What makes these suitable for molten salt electrolysis?

-

Titanium Electrode for High-Temperature Molten Salt Electrolysis offers exceptional corrosion resistance and high conductivity, making it ideal for demanding electrolytic processes.

-

Can the anode coating be customized?

-

Yes, we offer a range of coating options, including IrO2, RuO2, Pt, and more, to suit different applications.

-

What sizes are available for these?

-

Our anodes are customizable in terms of size and shape to accommodate various electrolytic setups.

Material Properties and Details

Titanium Electrode for Molten Salt Decomposition stands as a pinnacle in material choice, revered for its exceptional erosion resistance and remarkable strength-to-weight ratio, rendering it an optimal candidate for a spectrum of electrolytic applications.The selection of coating, including IrO2, RuO2, Pt, among others, is influenced by the electrolyte composition and operational parameters. Platinum coatings, renowned for their high conductivity and durability, excel in environments demanding robust performance. Meanwhile, IrO2 and RuO2 coatings emerge as stalwarts of stability and catalytic activity, ensuring steadfast operation even amidst challenging conditions. Each coating, meticulously chosen based on its unique properties, contributes to the overall efficacy and longevity of the electrolytic system, underscoring the importance of tailored solutions in optimizing performance.

Tai Ding Shuo Industrial Co., Ltd.

As a professional manufacturer and supplier of Titanium anodes for molten salt electrolysis, Tai Ding Shuo Industrial Co., Ltd. is committed to delivering top-quality products and services to our global clientele. We provide various standard and customized certifications, complete test reports, and support OEM requirements. With our fast delivery, secure packaging, and comprehensive testing support, we ensure a seamless experience for our customers. For inquiries or to discuss your specific electrolysis needs, please contact us at fujianguo@shelllaiqi.com.

With a focus on professionalism and excellence, Tai Ding Shuo Industrial Co., Ltd. is your trusted partner for innovative electrolytic solutions.