Product Description

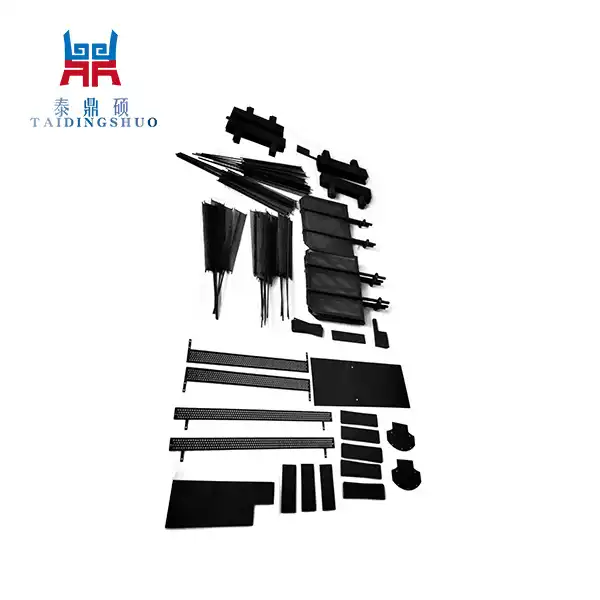

The Titanium Anode, which was developed specifically for the production of Tetramethylammonium Hydroxide (TMAH), is now available from Tai Ding Shuo Industrial Co., Ltd., a leading chemical manufacturer and supplier. We give a predominant item that fulfills the rigid necessities of contemporary synthetic cycles thanks to our obligation to greatness and long periods of involvement.

Product Details

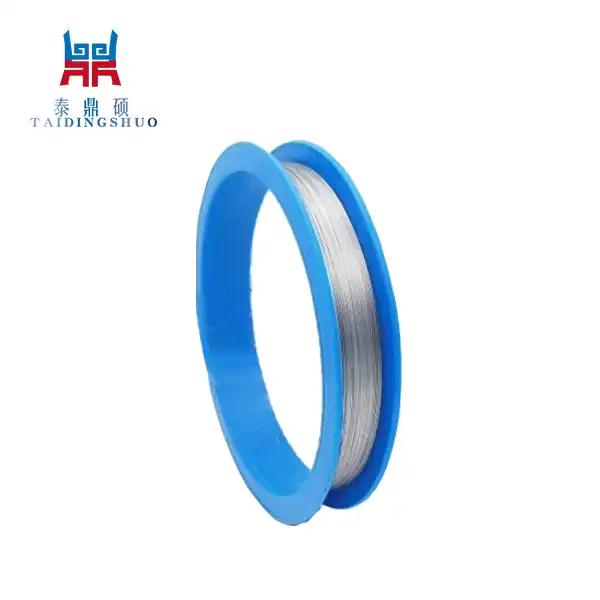

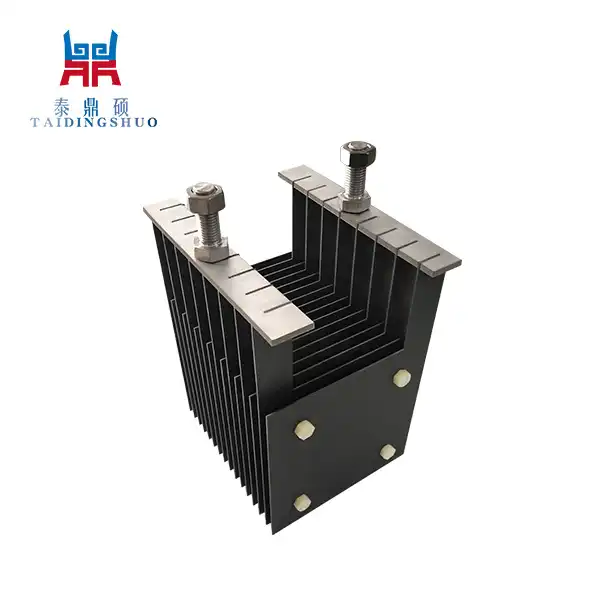

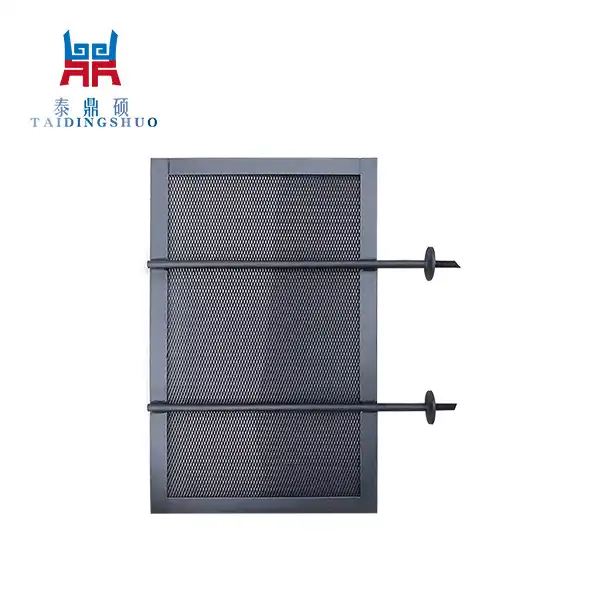

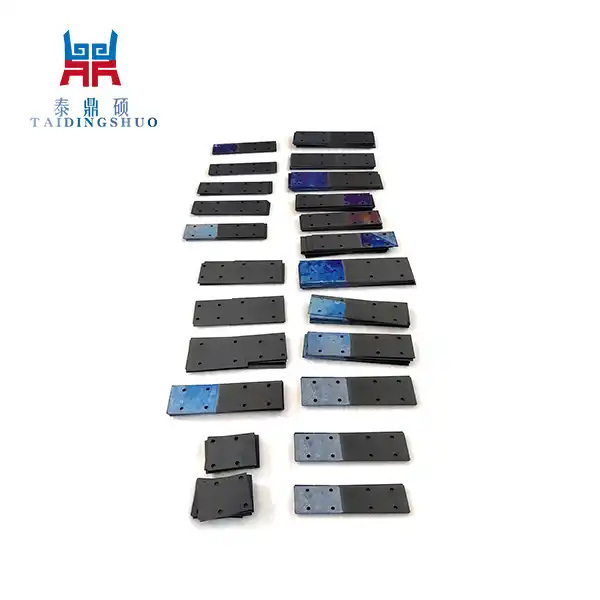

Our Titanium Electrode for Tetramethylammonium Hydroxide Synthesis for TMAH preparation is meticulously crafted using high-grade titanium, ensuring durability and corrosion resistance. The anode features a specialized structure optimized for efficient electrolysis, facilitating the production of TMAH with high purity and yield.

Product Standards

| Standard | Details |

|---|---|

| Material | High-grade Titanium |

| Coating | IrO2/RuO2 |

| Dimension | Customizable |

| Electrolyte | TMAH solution |

| Temperature Range | Ambient to elevated temperatures |

| Current Density | Adjustable |

| Electrolysis Method | Electrochemical |

Basic Parameters

- Voltage: Customizable

- Current Efficiency: High

- Lifetime: Extended service life

- Operating pH Range: Wide range compatibility

Product Attributes

- High corrosion resistance

- Excellent conductivity

- Long-lasting performance

- Customizable design

- Environmentally friendly

Product Functions

The Titanium Anode facilitates the electrolysis process necessary for the preparation of Tetramethylammonium Hydroxide. It serves as a reliable catalyst, ensuring efficient conversion of precursor materials into TMAH with exceptional purity.

Features

- Precise design for optimized performance

- Resistance to harsh chemical environments

- Enhanced durability for prolonged use

- Compatibility with various electrolyte solutions

Advantages and Highlights

Predominant Erosion Obstruction Guarantees Life span:

Even in harsh environments, the material's unrivaled resistance to corrosion ensures a long service life. By enduring destructive components, including synthetic substances and dampness, the item keeps up with its respectability over the long haul, lessening the requirement for successive substitutions and limiting free time. In a variety of applications, from industrial processes to infrastructure components, this durability results in cost savings and increased reliability.

Production that is cost-effective requires high current efficiency:

With its high flow proficiency, the item augments the use of electrical energy during electrolysis processes, prompting more practical creation strategies. Industries can increase productivity and reduce operational costs by minimizing energy losses and optimizing resource utilization. The proficient change of electrical energy into compound responses upgrades generally process effectiveness, going with it an optimal decision for electrolytic applications in areas like metal refining, synthetic blend, and energy stockpiling.

Dimensions that can be changed to fit specific applications:

The item's adaptable aspects offer flexibility and versatility to suit many applications and prerequisites. Whether it's breadth, length, or shape, customization choices consider custom-made arrangements that exactly address the issues of explicit businesses and cycles. Manufacturers are able to optimize the design and performance of their equipment as a result of this adaptability, resulting in enhanced product quality, efficiency, and functionality.

Increased conductivity makes electrolysis more efficient:

By optimizing current flow and reducing electrical resistance, the material's enhanced conductivity makes efficient electrolysis possible. This property is especially favorable in electrolytic cycles where conductivity straightforwardly influences response rates and energy utilization. Enhanced conductivity contributes to greater process efficiency, shorter processing times, and lower energy costs by facilitating smoother electron transfer and lowering voltage losses.

Application Areas

- Chemical synthesis

- Semiconductor manufacturing

- Pharmaceutical industry

- Research laboratories

OEM Services

Tai Ding Shuo Industrial Co., Ltd. offers OEM services, providing tailored solutions to meet specific customer requirements. Our team of experts collaborates closely with clients to develop custom Titanium Electrode for Tetramethylammonium Hydroxide Manufacturing optimized for their unique applications.

Certifications:

FAQs

1.What is the suggested voltage for electrolysis?

Depending on requirements and electrolyte concentration, voltage can be adjusted.

2.Might the anode at any point be utilized with other electrolyte arrangements?

The anode may be compatible with other electrolytes, subject to testing and compatibility analysis, despite its intended use for TMAH preparation.

3.What is the run of the mill life expectancy of it?

The anode has a long service life, ensuring consistent performance for a long time.

About Tai Ding Shuo Industrial Co., Ltd.

Tai Ding Shuo Industrial Co., Ltd. is a reputable manufacturer and supplier of high-quality Titanium Anodes for various chemical applications. We pride ourselves on delivering products that meet stringent quality standards and exceed customer expectations. With comprehensive certifications, complete test reports, and dedicated OEM services, we are your trusted partner for all these needs.

For inquiries or to place an order, please contact us at: fujianguo@shelllaiqi.com. Experience the reliability and performance of it for TMAH preparation today!