Product Description

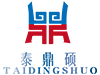

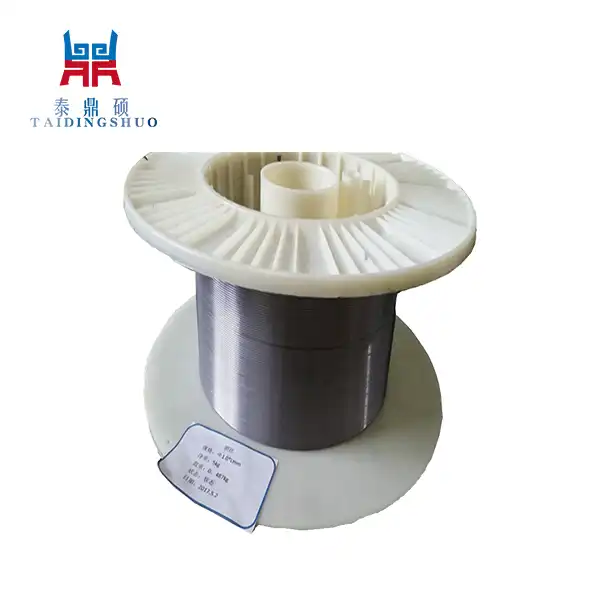

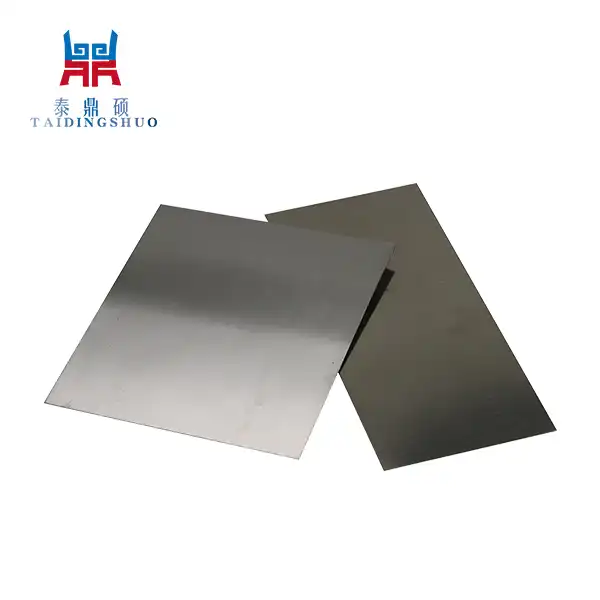

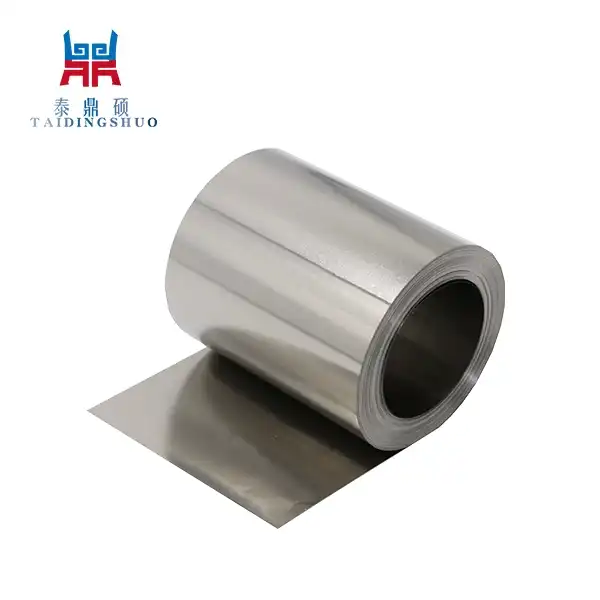

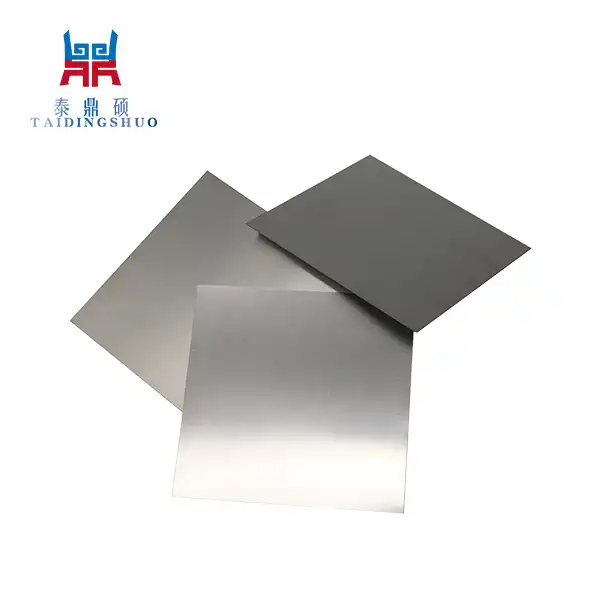

Zr1 zirconium Plates, offered by Tai Ding Shuo Industrial Co., Ltd., stand as premium choice for various industrial applications requiring robust, corrosion-resistant materials. Crafted with precision and expertise, our zirconium plates ensures high-quality performance and reliability in demanding environments.

Product Standards:

Tai Ding Shuo Industrial Co., Ltd. adheres to strict industry standards in the production of Zr1 zirconium plates, including ASTM B551 and ASTM B352, ensuring conformity and reliability in every plate manufactured.

Basic Parameters:

| Parameter | Specification |

|---|---|

| Material | Zr1 Zirconium |

| Thickness | 0.1mm - 50mm |

| Width | Up to 1000mm |

| Length | Up to 3000mm |

| Surface Finish | Polished or Matte |

| Density | 6.49 g/cm³ |

Product Attributes:

- High corrosion resistance

- Excellent thermal and electrical conductivity

- Superior strength-to-weight ratio

- Non-magnetic and non-toxic

- Exceptional ductility and formability

Product Functions:

The product with a reasonable zirconium plate price serves as a versatile material suitable for various applications, including chemical processing, aerospace engineering, medical devices, and marine equipment. Its corrosion-resistant properties make it ideal for use in harsh environments where traditional materials may fail.

Features:

- Precision-engineered for optimal performance

- Consistent thickness and flatness

- Smooth surface finish

- Easy to fabricate and machine

- Long-lasting durability

Advantages and Highlights:

- Enhanced corrosion resistance compared to titanium and stainless steel

- Suitable for high-temperature applications

- Lightweight yet durable construction

- Resistant to chemicals, acids, and alkalis

- Low maintenance requirements

Application Areas:

- Compound Handling: They are broadly utilized in substance handling businesses, especially for hardware presented to destructive conditions. They are used in the development of reactors, heat exchangers, and vessels for the creation of acids, soluble bases, and other destructive synthetic compounds.

- Atomic Industry: They are fundamental parts in atomic reactors because of their magnificent neutron assimilation properties and protection from erosion in high-temperature water and steam conditions. They are utilized in the creation of fuel cladding, underlying parts, and other basic reactor parts.

- Clinical Inserts: They are biocompatible and non-poisonous, making them appropriate for clinical embed applications. They are utilized in the assembling of dental inserts, prosthetic gadgets, and muscular inserts because of their similarity with the human body and protection from consumption in physiological conditions.

- Aviation and Safeguard: They are used in aviation and protection applications where lightweight, high-strength materials with great erosion opposition are required. They find use in airplane parts, rocket designs, and shuttle because of their capacity to endure outrageous circumstances and conditions.

- Hardware:They are utilized in the gadgets business for their conductivity and protection from erosion. They are utilized in the development of capacitors, terminals, and other electronic parts where stable electrical execution and toughness are fundamental.

- Marine Designing: They are utilized in marine designing for their protection from saltwater erosion. They track down applications in the development of boat parts, seaward stages, and seawater desalination gear, where erosion opposition is basic for long haul execution.

- Desalination Plants: They are used in the development of gear for desalination plants because of their protection from erosion via seawater and salt water arrangements. They are utilized in heat exchangers, siphons, and funneling frameworks for the development of freshwater from seawater.

- Food and Drug Handling: They are utilized in food and drug handling enterprises where consumption opposition and cleanliness are central. They are utilized in the manufacture of gear, for example, reactors, capacity tanks, and channeling frameworks for the creation of drugs and food items.

OEM Services:

Tai Ding Shuo Industrial Co., Ltd. offers comprehensive OEM services, allowing customers to customize Commercial Grade Zirconium Plate according to their specific requirements. Our experienced team ensures the highest quality standards and timely delivery for OEM projects.

Certifications:

FAQs:

- What are the key properties of the product?

- It boasts high corrosion resistance, excellent thermal conductivity, and exceptional strength-to-weight ratio.

- Can the product withstand high temperatures?

- Yes, it is suitable for high-temperature applications, making it ideal for use in demanding environments.

- Is the product non-magnetic?

- Yes, it is non-magnetic, making it suitable for applications where magnetic interference is a concern.

Material Properties and Details:

-

Corrosion Resistance: It exhibits outstanding resistance to corrosion, even in harsh chemical environments, making it ideal for use in corrosive applications.

-

Thermal Conductivity: With its excellent thermal conductivity, it efficiently transfers heat, making it suitable for heat exchanger and thermal management applications.

-

Electrical Conductivity: It offers good electrical conductivity, making it suitable for electrical components and applications requiring electrical conductivity.

About Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a professional manufacturer and supplier of Commercial Grade Zirconium Plate, offering various standard and customized options to meet the diverse needs of our customers. We provide complete room certifications and test reports, ensuring the highest quality and reliability of our products. With our OEM services, fast delivery, and tight packaging, we strive to exceed customer expectations. For inquiries or to order the product,please contact us at fujianguo@shelllaiqi.com.

With Tai Ding Shuo Industrial Co., Ltd., you can trust in our expertise and commitment to delivering top-quality product with a reasonable zirconium plate price for your industrial needs.