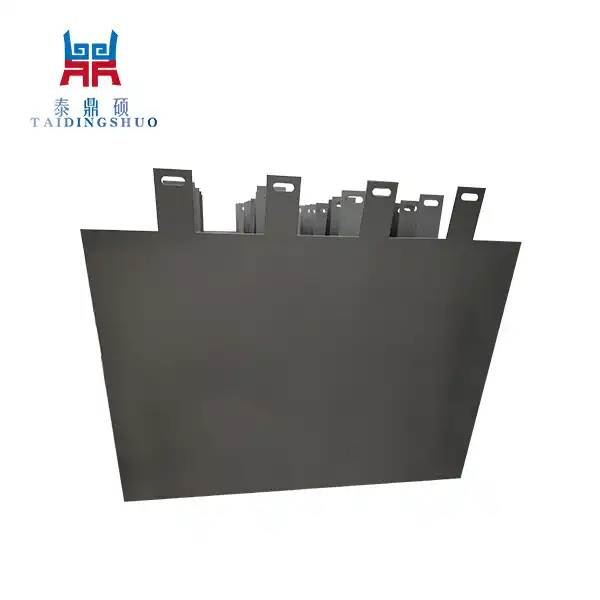

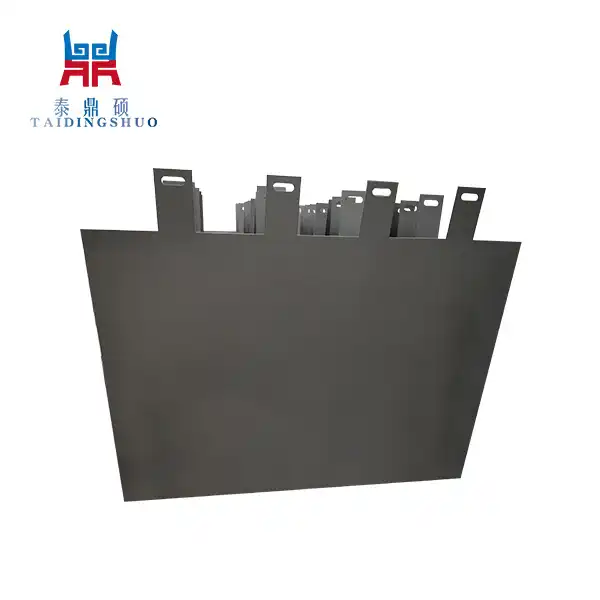

Product Description

Due to their excellent performance and durability in harsh chemical environments, titanium anodes are frequently utilized in the electrolytic extraction of metals from chloride solutions. In this cycle, it assume a pivotal part in working with the electrochemical responses that convert metal particles in chloride arrangements into unadulterated metal stores.

The resistance to corrosion is one of the main benefits of using them in electrolytic metal extraction. Chloride arrangements are known to be exceptionally destructive, however it can endure these unforgiving circumstances without crumbling or corrupting after some time. As a result, titanium anodes are a dependable and durable choice for metal extraction processes.

Additionally, the high electrical conductivity of it makes it possible to transfer electrons effectively throughout the electrolytic process. This outcomes in quicker testimony of metal particles onto the cathode, prompting higher creation rates and expanded productivity in metal extraction.

One more advantage of involving it in the electrolytic extraction of metals is their capacity to work at high current densities. This considers the handling of huge volumes of chloride arrangement and the extraction of metals on a business scale. Titanium anodes can be effortlessly increased to satisfy the needs of modern metal extraction processes.

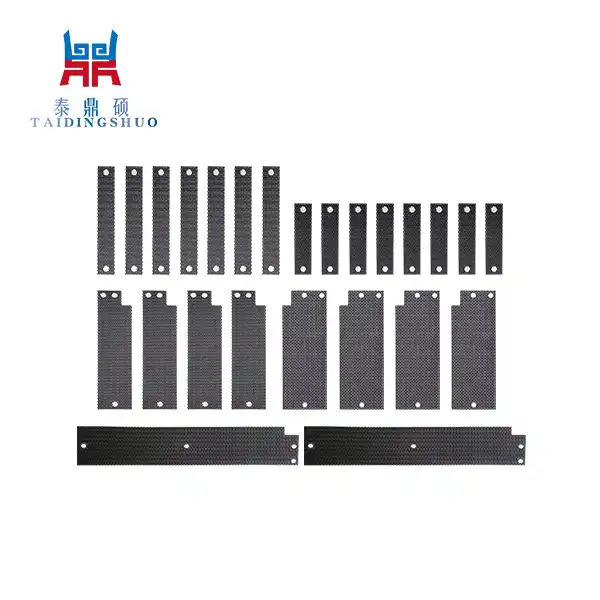

Moreover, it can be tweaked to suit explicit metal extraction necessities. They can be designed with specific geometries to optimize the electrochemical process or coated with a variety of materials to improve their performance. This adaptability takes into account the improvement of metal extraction processes for various kinds of metals and chloride arrangements.

In general, the electrolytic extraction of metals from chloride solutions relies heavily on it. They are favored for industrial metal extraction processes due to their corrosion resistance, high conductivity, capacity to operate at high current densities, and customization options. As the interest for practical and productive metal extraction strategies keeps on developing, they are probably going to assume an undeniably significant part in the extraction of metals from chloride arrangements.

Material Properties:

| Property | Details |

|---|---|

| Corrosion Resistance | Excellent resistance to corrosion in chloride solutions. |

| Conductivity | High conductivity, ensuring efficient electrochemical performance. |

| Durability | Exceptional durability for prolonged service life. |

| Biocompatibility | Titanium is biocompatible and suitable for various industrial applications. |

Certifications and Support:

| Service | Details |

|---|---|

| Certifications | Various standard and customized room certifications available. |

| Test Reports | Complete test reports provided for quality assurance. |

| OEM Support | Comprehensive OEM services offered to meet client specifications. |

| Delivery | Fast delivery options available for timely project completion. |

| Packaging | Secure and tight packaging ensures product integrity during transit. |

| Customer Support | Dedicated customer support for inquiries and assistance. |

Product Standards:

- Compliant with international industry standards for electrolytic processes.

- Manufactured using high-quality titanium materials to ensure durability and longevity.

- Rigorous quality control measures ensure consistent and reliable performance.

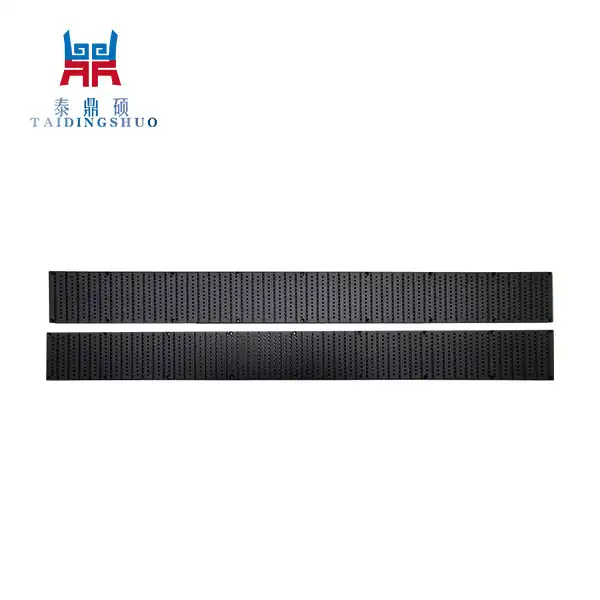

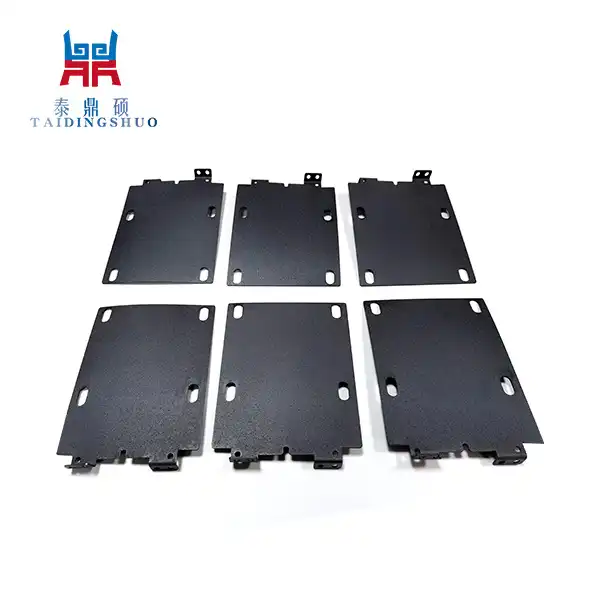

Basic Parameters:

- Material: Coating in Titanium

- Dimensions of Mixed Metal Oxide (MMO)

- Based on the needs of the customer

- customizable Current Density: Up to 2000 A/m²

- Working TemperatureElectrolyte: Up to 80°C Chloride Arrangement

Product Attributes:

- Corrosion resistance: Excellent resistance to corrosion ensures prolonged service life.

- High efficiency: Optimized design for enhanced electrochemical performance.

- Customizability: Tailored solutions to meet specific application requirements.

- Eco-friendly: Facilitates environmentally friendly metal extraction processes.

- Low maintenance: Minimal maintenance requirements for cost-effective operation.

Product Functions:

Titanium niobium oxide anode assume a significant part in the electrolytic extraction of metals from chloride arrangements. Here are the essential elements of it in this cycle:

- Chloride ion oxidation:The oxidation of chloride ions (Cl-) in the electrolyte solution is made easier by it. At the anode surface, this electrochemical reaction produces chlorine gas (Cl2).

- Current Appropriation:It ensure that the electrolytic cell receives the same amount of current throughout. This is significant for effective metal extraction and to forestall restricted over-oxidation or under-extraction. Its effective current distribution capabilities are made possible by their high electrical conductivity and low oxygen evolution.

- Electrocatalytic Movement:It show electrocatalytic action towards the oxidation of specific metal particles in chloride arrangements. By lowering the overpotential required for metal deposition, this electrocatalytic effect improves the efficiency of metal extraction.

- Protection from Corrosion:In chloride solutions, they are highly resistant to corrosion. The development of a defensive oxide layer on the titanium surface forestalls further erosion and guarantees long haul steadiness of the anode. This consumption obstruction is urgent for keeping up with the trustworthiness and execution of the anode overstretched times of activity.

- Chlorine Development Control:It assume a part in controlling the development of chlorine gas at the anode surface. The low oxygen advancement capability of titanium limits the development of hypochlorite particles (OCl-), which can slow down metal extraction and lessen current effectiveness.

When it comes to electrolytically extracting metals from chloride solutions, titanium niobium oxide anode are on the whole, extremely durable and effective electrode materials. They are excellent candidates for this strenuous industrial process due to their distinctive properties and adaptability.

Features:

- Uniform current distribution for consistent metal deposition.

- Enhanced durability and longevity for extended service life.

- Stable performance across a wide range of operating conditions.

- Low voltage drop for energy-efficient operation.

- Compatible with various electrolytic systems.

Advantages and Highlights:

- Superior corrosion resistance ensures durability in harsh environments.

- High current density capabilities for increased productivity.

- Customizable designs to accommodate specific project requirements.

- Eco-friendly alternative to traditional metal extraction methods.

- Cost-effective solution with minimal maintenance requirements.

Application Areas:

- Mining and metallurgy

- Electroplating

- Chemical processing

- Water treatment

- Electrorefining

OEM Services:

We offer comprehensive OEM services to meet the unique requirements of our clients. From customized designs to private labeling, we ensure that our products align perfectly with your brand and specifications.

FAQs:

-

How long do you anticipate your product to last for?

The service life of our product ranges from three to five years, depending on operating conditions and maintenance procedures.

-

Are you able to provide individualized dimensions for particular applications?

Indeed, we work in giving tailor-made answers for meet the exact necessities of our clients. We will deliver in accordance with your requirements if you simply provide them to us.

-

Is your product appropriate for high-temperature applications?

Indeed, our Titanium Substrate Anodes for Metal Extraction from Chloride Solutions is intended to endure temperatures of up to 80°C, making it reasonable for many modern cycles.

Material Properties and Details:

- Titanium: Known for its exceptional corrosion resistance and biocompatibility, titanium is an ideal choice for electrolytic applications.

- Mixed Metal Oxide (MMO) Coating: Applied to enhance conductivity and corrosion resistance, MMO coating ensures optimal performance in chloride solutions.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Current Co., Ltd., a significant maker and provider of Titanium Substrate Anodes for Metal Extraction from Chloride Solutions for Electrolytic Extraction of Metals from Chloride Plan, is focused on giving items and administrations of the greatest conceivable quality. To meet the various requirements of our global clients, we offer OEM support, comprehensive test reports, custom and standard certifications, and other services. We try to meet and outperform client presumptions by giving brief movement, secure packaging, and gave client help. Please contact us at fujianguo@shelllaiqi.com if you have any questions or need a quote.