Product Description

Titanium anodes have become progressively famous lately for the creation of electrolytic silver impetuses. In comparison to conventional materials like graphite or platinum, these anodes have a number of advantages, including high efficiency, low cost, and superior resistance to corrosion.

One of the vital advantages of utilizing it is their excellent erosion obstruction. Titanium is profoundly impervious to consumption in a large number of conditions, including acidic and soluble arrangements. Because of this, they are ideal for use in electrolytic processes that are subjected to harsh chemical conditions. These processes ensure that it will have a longer lifespan and require less upkeep than other materials.

Notwithstanding their erosion opposition, it likewise offer high effectiveness in electrolytic cycles. During electrolysis, titanium's high conductivity enables effective electron transfer, accelerating reaction rates and increasing product yields. Utilizing it in their production processes, this may result in increased productivity and cost savings.

In addition, titanium anodes are less expensive than those made of platinum or other materials. While platinum is a profoundly viable impetus material, it is likewise costly and can drive up creation costs fundamentally. Titanium, on the other hand, is cheaper and easier to find, making it a more cost-effective option for businesses looking to improve their manufacturing processes.

In general, the production of electrolytic silver catalysts can benefit from the superior corrosion resistance, high efficiency, and cost-effectiveness of it. As the interest for excellent impetus materials keeps on developing, Titanium Silver Catalyst Anodes are probably going to assume an undeniably significant part in the creation of electrolytic silver impetuses.

Product Standards:

- Compliant with international standards for its manufacturing.

- Rigorous quality control measures ensure adherence to industry regulations.

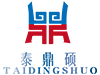

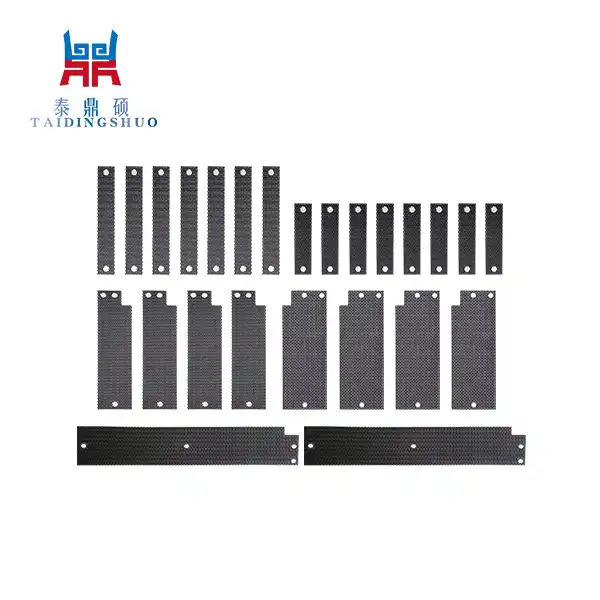

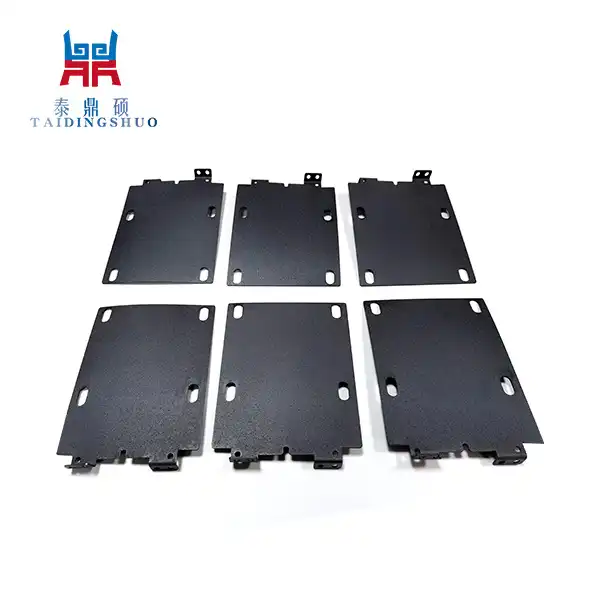

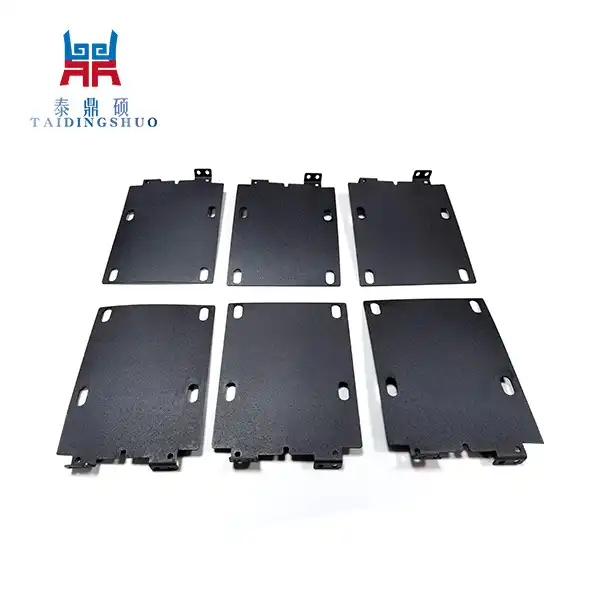

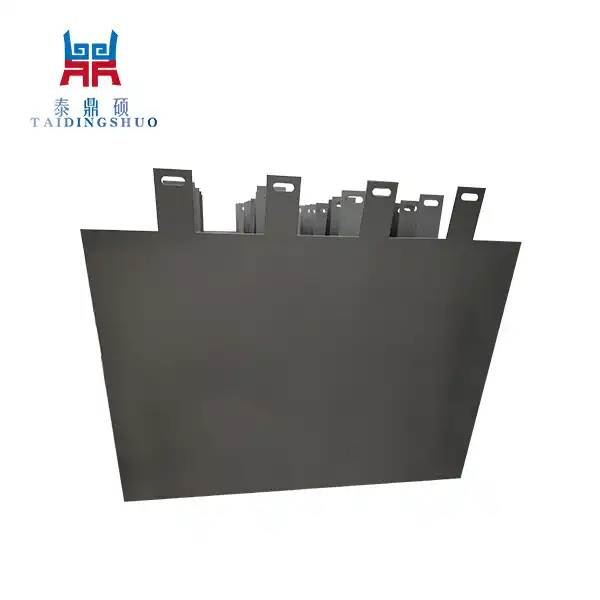

Basic Parameters:

- Material: Titanium

- Coating: Ruthenium-Iridium or Platinum

- Dimensions: Customizable based on client requirements

- Current Density: Tailored to specific applications

Product Attributes:

- High corrosion resistance

- Excellent conductivity

- Longevity and durability

- Consistent performance

- Customizable designs

Product Functions:

Titanium anodes assume a critical part in the creation of electrolytic silver impetuses by filling in as the terminal through which the electrochemical responses happen. These anodes offer a few key capabilities that are fundamental for the proficient and viable creation of top notch silver impetuses.

It provide the electrolytic process with a stable and inert surface first and foremost. The high consumption obstruction of titanium guarantees that the anode stays in salvageable shape and doesn't corrupt during the electrolysis cycle, considering steady and solid creation of silver impetuses. Maintaining the purity and quality of the finished product necessitates this stability.

Moreover, it work with the electrochemical responses that are important for the development of silver impetuses. At the point when an electric flow is applied to the electrolyte arrangement containing silver particles, the it goes about as the site for oxidation responses to happen. This outcomes in the testimony of silver metal onto the outer layer of the anode, which can then be reaped and utilized as an impetus in different compound cycles.

Additionally, the high conductivity of it enables quick electron transfer during electrolysis. This advances quicker response rates and better returns of silver affidavit, prompting expanded efficiency and cost-viability in the creation cycle. Additionally, the electrolytic process's overall efficiency and energy consumption are improved by titanium's high conductivity.

In general, Titanium Silver Catalyst Anodes play a variety of roles in the production of electrolytic silver catalysts. They give a steady and idle surface for electrochemical responses, work with the statement of silver metal, and proposition high conductivity for effective electron move. These capabilities are fundamental for guaranteeing the quality, virtue, and proficiency of the silver impetus creation process, making it an imperative part in this industry.

Features:

- Advanced coating technology for enhanced catalytic activity

- Robust construction for prolonged service life

- Low maintenance requirements

- Superior performance under extreme operating conditions

Advantages and Highlights:

- Optimal catalytic efficiency

- Reduced energy consumption

- Minimal downtime

- Cost-effective solution for catalyst production

Application Areas:

- Chemical industry

- Pharmaceutical manufacturing

- Petrochemical refineries

- Electroplating processes

OEM Services:

To meet our customers' specific needs, we provide OEM services. Our knowledgeable staff closely works with clients to create bespoke applications-specific solutions.

Certifications:

FAQs:

-

Q: What is the recommended maintenance schedule for it?

-

A: Maintenance requirements vary depending on operating conditions. However, regular inspections and cleaning are recommended to ensure optimal performance.

-

Q: Can the dimensions of the anodes be customized?

-

A: Yes, we offer customizable dimensions to suit the unique specifications of each application.

-

Q: What is the typical lifespan of it?

-

A: With proper maintenance, it can last for several years, providing long-term reliability and performance.

Material Properties and Details:

Titanium is chosen for its exceptional resistance to corrosion, which makes it suitable for harsh industrial settings. The expansion of ruthenium-iridium or platinum coatings improves conductivity and reactant action, guaranteeing effective electrolytic cycles.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a leading manufacturer and supplier of anodizing titanium cathode for electrolytic silver catalyst production. We adhere to stringent quality standards and offer a comprehensive range of certifications and test reports to guarantee product excellence. Our OEM services, fast delivery, and attentive customer support make us the preferred choice for discerning buyers worldwide. For inquiries or orders, please contact us at fujianguo@shelllaiqi.com.

In conclusion, our anodizing titanium cathode for electrolytic silver catalysts represent a pinnacle of engineering excellence, delivering superior performance, reliability, and cost-effectiveness for industrial applications. Trust Tai Ding Shuo Industrial Co., Ltd. for all your titanium anode needs.